Description

PRODUCT DESCRIPTION

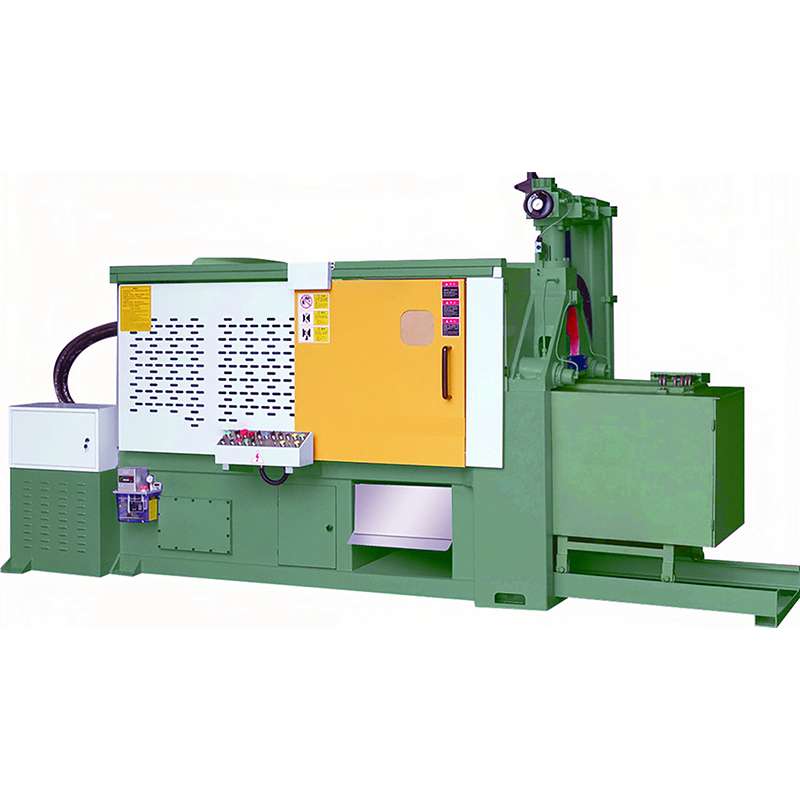

90 Tons Hot Chamber Die Casting Machine

| ITEM | UNIT | PARAMETER | ITEM | UNIT | PARAMETER |

| Clamp force | KN | 900 | Stroke far from nozzle |

mm | 270 |

| Clamping stroke | mm | 300 | Punch diameter | Kg | 45/50/55 |

| Ejecting force | KN | 70 | Weight of shot material/Zn |

Kg | 1.0/1.26/1.53 |

| Ejection stroke | mm | 60 | Capacity of crucible/Zn |

Kg/Zn | 480 |

| Mold thickness | mm | 130-430 | Motor power | KW | 11 |

| Platen Size(W×H) | mm | 600*600 | System working pressure |

MPa | 11 |

| Tiebar spacing(WxH) |

mm | 400*400 | Furnace(oil) | Kg/h | 4.8 |

| The diameter of Tiebar |

mm | 70 | Electric furnace | Kw | 30 |

| Position of shot material |

mm | 0 | Oil tank volume | L | 250 |

| Force of shot material |

KN | 90 | Shot nozzle heating power |

Kw | 2 |

| Stroke of shot material |

mm | 130 | Size of body shape |

mm | 4200*1450 *2050 |

Advantages:

Our 90T die-casting machine adopts five points mould clamping mechanical automatic adjusting mould to increase the machine performance. It adopts automatic oil supply system and the steel pins and tie bats are not easy to broken.It adopts buckle nozzle cylidner to increase workign effiency.