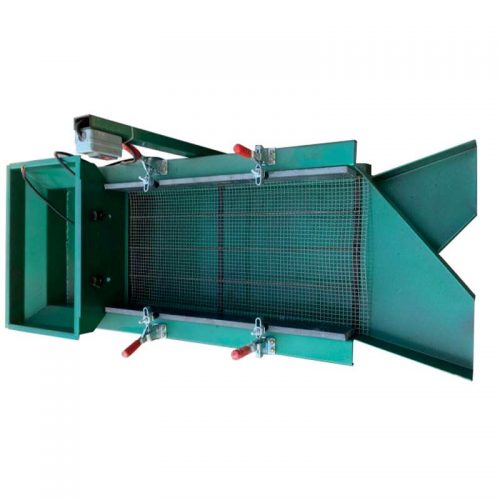

Description

| Output | For slider is about 20kg/time/40-50mintes For puller is about 25kg/time/40-50minutes |

Advantages:

This machine is good for polishing the small spare parts on the slider, for example: monkey, hook, flat puller. So it is good for polishing YG puller and spring. The speed is more quickly and it is suitable for zinc, iron, brass and other material.The result is not very good for polishing slider because it will hit some slider when it runs quickly.

1. Centrifugal Force: A centrifugal type polishing machine utilizes centrifugal force to propel the polishing media or abrasives against the workpieces. It has a rotating chamber or bowl where the workpieces are placed. As the bowl spins rapidly, the centrifugal force generated causes the polishing media or abrasives to move outward. This force ensures efficient and powerful polishing action on the workpiece surfaces.

2. Fast and Efficient Polishing: The centrifugal motion of the polishing machine enables fast and efficient polishing of the workpieces. The high rotational speed of the bowl creates a strong centrifugal force, which produces intense impacts between the polishing media or abrasives and the workpiece surfaces. This rapid and powerful polishing action reduces the polishing time, making the centrifugal type polishing machine suitable for large-scale production environments.

3. Uniform Polishing: Centrifugal type polishing machines ensure uniform polishing across the workpiece surfaces. As the polishing media or abrasives are propelled outward by the centrifugal force, they make contact with all areas of the workpieces. This results in a consistent and even finish, even on complex shapes or hard-to-reach areas. The uniformity of polishing is essential for maintaining product quality and appearance.

4. Versatile Applications: Centrifugal type polishing machines are versatile and can be used for various materials and workpiece sizes. They can effectively polish metals, plastics, ceramics, glass, and other materials. Whether it’s small components or larger parts, the centrifugal force generated in the machine ensures thorough and high-quality polishing results. This versatility makes them suitable for industries such as jewelry making, metalworking, and surface finishing.

5. Surface Restoration and Finishing: These machines are highly effective in restoring worn-out or damaged surfaces to their original shine. They can remove scratches, oxidation, burrs, and other surface imperfections, resulting in an improved appearance and quality of the workpieces. Additionally, centrifugal type polishing machines can achieve different levels of surface finishes, allowing for customization based on specific requirements.