Description

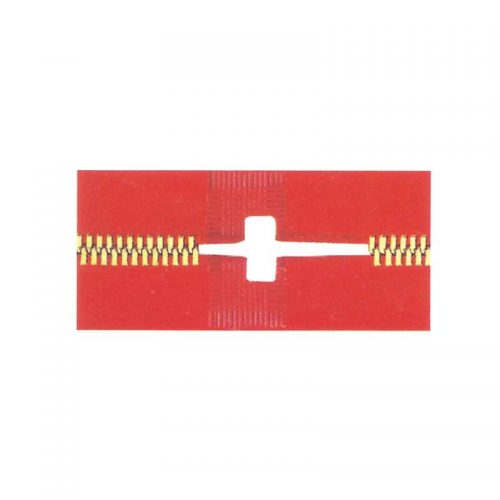

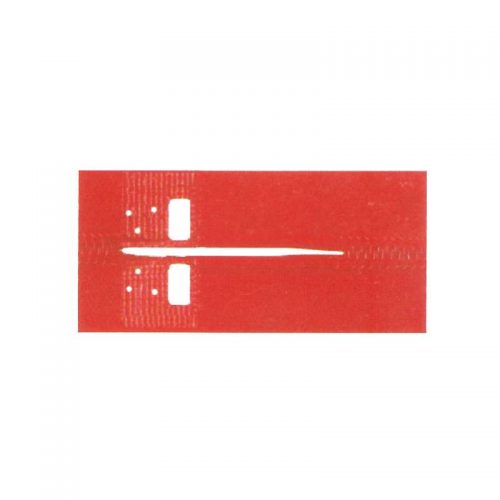

Product Name: Hole Punching Mould for Zipper

Model number : QLQ-HPMZ

Summary : Required machine: hole punching machine for nylon zipper, plastic zipper and metal zipper; Available products: open-end zippers.

Advantages:

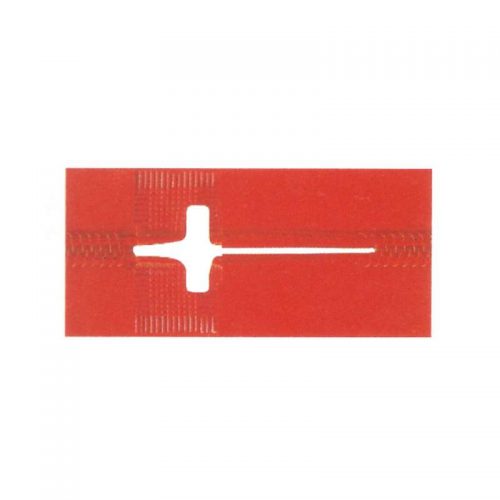

- Precision manufacturing: The Hole Punching Mould is manufactured with precision to ensure accurate hole placement and consistent results. This precision guarantees that the holes are aligned perfectly with the zipper teeth, providing a secure and convenient attachment point.

- Durable materials: The Hole Punching Mould is built using durable materials that can withstand repeated use and the forces involved in the hole punching process. This ensures long-lasting performance and reliability.

- Seamless integration: The Hole Punching Mould can be seamlessly integrated into existing zipper production processes, compatible with various zipper types and sizes. It allows for efficient and smooth operation, optimizing workflow and reducing production time.

- Enhanced functionality: The Hole Punching Mould plays a vital role in creating clean and uniform holes in zippers. It ensures consistent hole diameter, shape, and spacing, resulting in professional-looking zippers that are easy to handle and attach.

- Improved production efficiency: By incorporating the Hole Punching Mould into zipper production, manufacturers can enhance production efficiency. The precise design and reliable performance of the mould facilitate faster and more consistent hole punching, reducing production time and increasing output.

- Cost-effectiveness: The Hole Punching Mould’s durable construction minimizes the need for frequent maintenance or replacements, providing manufacturers with a cost-effective solution. It helps to optimize production costs and improve overall productivity in zipper manufacturing processes.