Description

PRODUCT DESCRIPTION

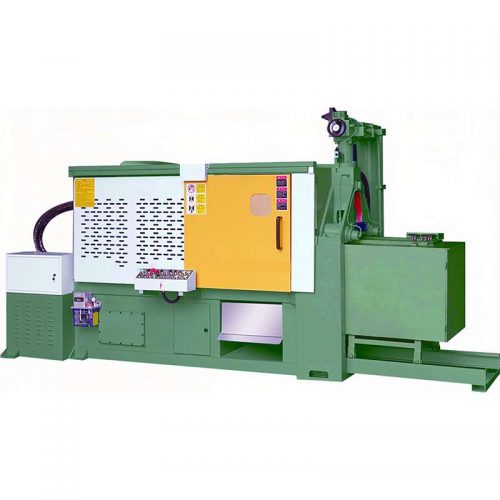

Automatic Barrel Separating Machine

| Machine motors | 4 ( 0.75 watts*2, 0.55 watts*2) |

| Hourly electricity consumption | 1.6kw |

| machine random accessories | 2 sets of sensor, 2 sets of stroke switch ,1 manual |

| Machine Drum size (Length*Width*Height) | 1.5*0.86*2.5m |

| Conveyor Belt Size (Length*Width*Height) | 1.5*0.38*1.3m |

| Riser Size (Length*Width*Height) | 0.8*0.6*2.25m |

Advantages:

Power saving and easy to operate. It saves 1 kilowatt of electricity in one hour. (2 motors with 0.75 watt motor, plus 1 motor with 0.55 watt motor, work only half an hour in one hour of operation). There is no need to adjust the frequency of this machine.

Small footprint. The total area of the whole automatic separation and polishing drum plus die casting machine is 8 Square.

Save labor, clean ground. A worker can probably see 6 / 7 machines only responsible for feeding and receiving without changing molds.

Large storage space and low noise level. The closed lifting drum can store 300 μ 400 touch and pull head pull piece, and the voice is basically lower than that of workshop die casting machine, while the conveyor belt is basically lower than that of workshop die casting machine. The maximum amount of money can only be stored 60 80 touch pull head pull piece.

The cooling time is long, the effect is good and does not deform, the product is separated clean and has no damage.

Good quality. Except that the sensor switch and stroke switch are broken, the machine will not fail.