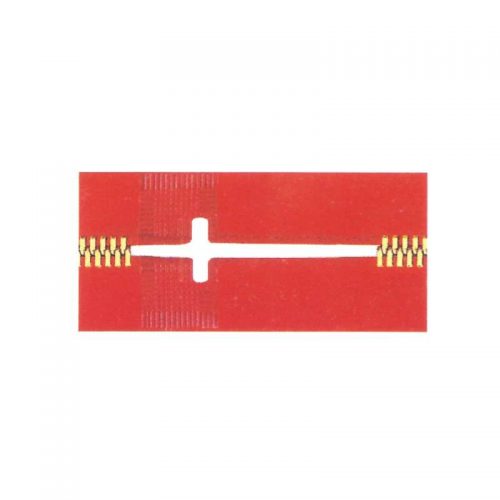

Description

Advantages:

- Precision manufacturing: The mould is manufactured with high precision, guaranteeing accurate dimensions and superior quality. It ensures perfect alignment between the mould and the pin box, resulting in precise and consistent cutting for injecting four holes.

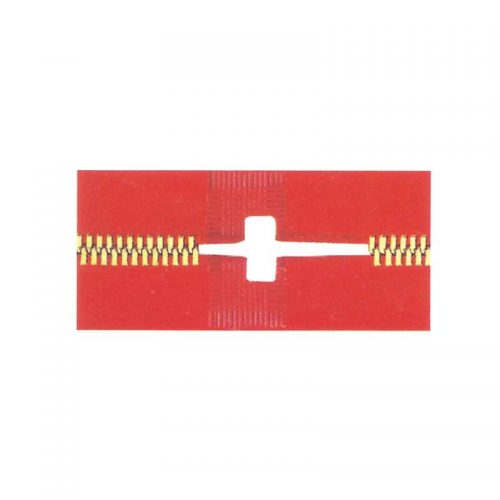

- Durable materials: Constructed using durable materials, the mould is built to withstand the pressures and forces involved in the injection process. It offers durability and long-lasting performance.

- Seamless integration: The 4 Holes Straight Cutting Punching Mould seamlessly integrates into the existing production system for nylon zipper pin box injecting. It is designed for easy installation and compatibility, allowing for a smooth workflow and minimizing disruptions.

- Enhanced functionality: This mould plays a crucial role in creating clean and uniform cuts for injecting four holes in the pin box. Its functionality contributes to the efficient and reliable performance of the injecting process.

- Improved production efficiency: By incorporating the 4 Holes Straight Cutting Punching Mould, manufacturers can enhance production efficiency. The precise design and reliable performance of the mould facilitate faster and more efficient injection, reducing production time and increasing output.

- Cost-effective: The durable construction of the mould minimizes the need for frequent maintenance or replacements, providing a cost-effective solution. It helps optimize production costs and improve overall productivity in the nylon zipper pin box injecting process.