Description

Summary : 1) Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth.

MOQ : 1 set

Lead time : 30 days

Export Packing : plywood

PRODUCT DESCRIPTION

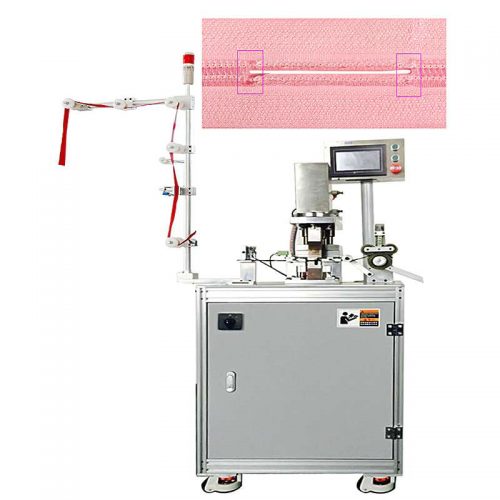

Automatic Nylon Zipper Double Trimming Gapping Machine (long model)

| MODEL NO. | QLQ-NGMC-1 | N.W(KG) | 400 | M/C SIZE(M) | 1.80*1.80*1.90 |

| AVG OUTPUT | 3800PCS/60CM/H | G.W(KG) | 470 | PKGS SIZE(M) | 1.55*0.95*1.80 |

| VOLTAGE(V) | 220V | POWER(KW) | 2.0 | PHASE(PH) | 1 |

Advantages:

1) Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth.

2) By adopting touch screen control, customers can adjust the machine gapping speed and gapping empty length optionally.

3) By adopting servo motor gapping and hooked needle gapping, this machine can control the accuracy of the gapping empty length better.

4) Normally, this machine is more correct to make the zippers with length between 15cm–100cm because the long distance between gapping mould and tape pulling part will cause the length can not be made correctly. But if the zipper length will be made between 15cm–100cm, then most customers will choose this model to get length almost without tolerance.If customers want to make the length less than 15cm or more than 100cm, then it is better to choose our another gapping machine QLQ-NGMC-2 which is more suitable for these sizes.