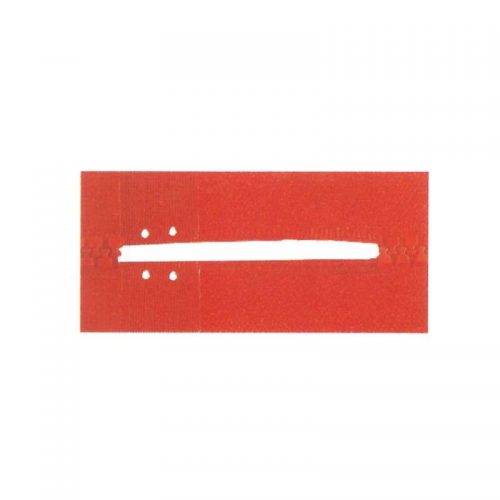

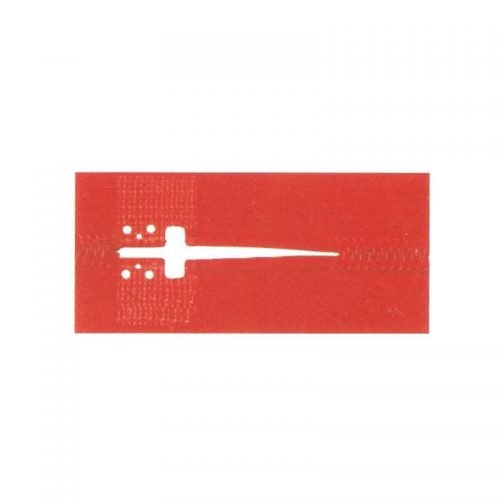

Description

Advantages:

- Precision manufacturing: The mould is manufactured with high precision, guaranteeing accurate dimensions and superior quality. It ensures perfect alignment between the mould and the pin, resulting in precise and consistent T-shaped cuts for secure attachment.

- Durable materials: Constructed using durable materials, the mould is built to withstand the pressures and forces involved in the injection process. It offers durability and long-lasting performance.

- Seamless integration: The 4 Holes T Cutting Punching Mould seamlessly integrates into the existing production system for nylon zipper pin injecting. It is designed for easy installation and compatibility, allowing for a smooth workflow and minimizing disruptions.

- Enhanced functionality: This mould plays a crucial role in creating clean and uniform T-shaped cuts in the pin, ensuring precise and secure attachment. Its functionality contributes to the efficient and reliable performance of the pin injecting process.

- Improved production efficiency: By incorporating the 4 Holes T Cutting Punching Mould, manufacturers can enhance production efficiency. The precise design and reliable performance of the mould facilitate faster and more efficient injection, reducing production time and increasing output.

- Cost-effective: The durable construction of the mould minimizes the need for frequent maintenance or replacements, providing a cost-effective solution. It helps optimize production costs and improve overall productivity in the nylon zipper pin injecting process.