Description

Advantages:

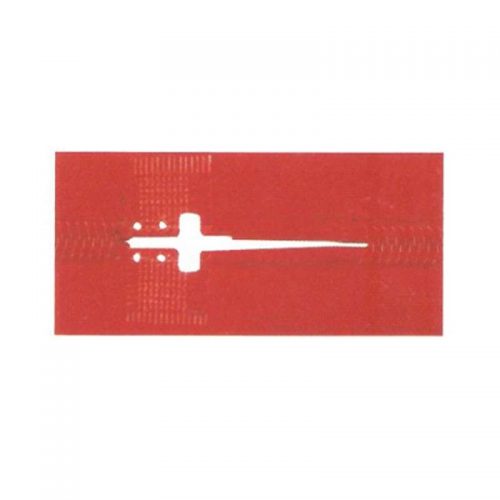

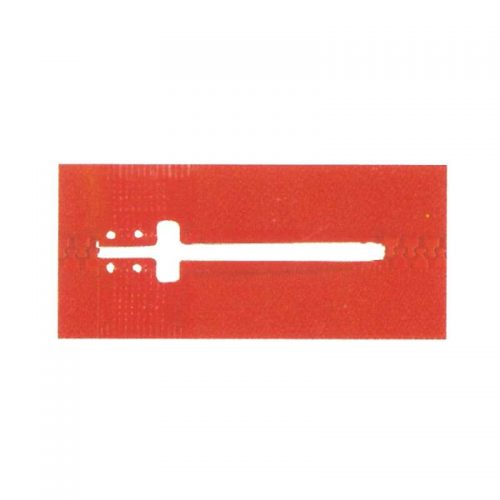

- Precision and durability: The 4 Holes T Cutting Punching Mould is designed with precision and durability in mind. It ensures accurate alignment and long-lasting performance when cutting T-shaped holes for injecting plastic zipper pin pins.

- Seamless integration: This mould seamlessly integrates into existing production systems for injecting plastic zipper pin pins. It easily fits with compatible equipment, ensuring a smooth workflow and minimal disruptions during the injection process.

- Enhanced functionality: With its precise cutting capability, the mould creates clean and uniform T-shaped holes in the plastic zipper pin pins. This facilitates secure attachment, ensuring precise positioning and enhancing the overall quality and reliability of the injection process.

- Improved efficiency: The 4 Holes T Cutting Punching Mould improves production efficiency by enabling faster and more efficient hole cutting. It reduces production time and increases output, leading to enhanced productivity in plastic zipper pin pin injection.

- Cost-effective solution: Built to last, this mould offers a cost-effective solution. Its durable construction reduces the need for frequent replacements, minimizing downtime and optimizing production costs in the plastic zipper pin pin injection process. This ultimately improves profitability and ensures long-term success.