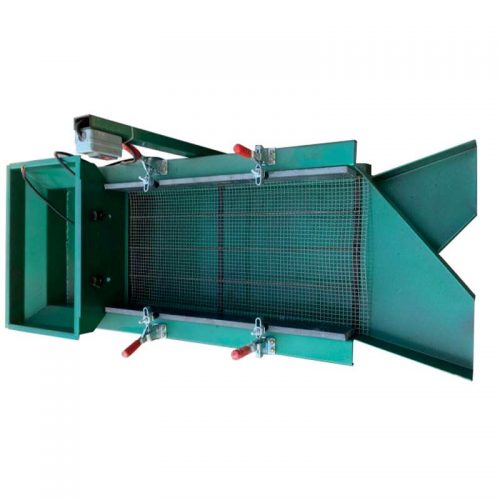

Description

1. Efficient Separation Process: The plastic product and frame separating machine automate the separation process, greatly improving efficiency and productivity. It eliminates the need for manual labor and reduces the time required to remove plastic products from their frames or molds, leading to faster production cycles.

2. Gentle Handling of Plastic Products: These machines are designed to handle plastic products with care to prevent any damage or deformation. They employ gentle separation techniques such as mechanical separation, suction, or specialized tools to ensure the integrity and quality of the plastic components, preserving their usability and functionality.

3. Customizable Separation Mechanisms: The machine offers customizable separation mechanisms to accommodate different types, shapes, and sizes of plastic products. It can be adjusted to handle various packaging configurations, molds, or frame designs, ensuring versatility and adaptability to meet specific industry requirements.

4. High Accuracy and Precision: The plastic product and frame separating machine employ precise mechanisms to separate individual plastic items accurately. This ensures that each product is efficiently released from its frame or mold without any damage or distortion. The high accuracy and precision minimize errors in the separation process, helping to maintain product quality and consistency.

5. Increased Workplace Safety: By automating the plastic product separation process, the machine improves workplace safety. It reduces the reliance on manual labor, minimizing the risk of injuries associated with handling sharp or bulky plastic components. Additionally, some machines incorporate safety features such as emergency stop buttons and protective guards to ensure operator safety.

6. Cost-effectiveness: The automation provided by a plastic product and frame separating machine leads to long-term cost savings for businesses. The machine’s high efficiency and productivity reduce labor costs and optimize resource allocation. It also minimizes the risk of errors and damage to plastic components, reducing waste and potential expenses associated with defects or rework.

7. Integration with Production Lines: These machines are designed to seamlessly integrate with existing production lines or plastic processing systems. By connecting the machine to the production line, plastic products can be directly fed into subsequent manufacturing, assembly, or packaging stages, improving overall workflow and reducing operational bottlenecks.