Description

PRODUCT DESCRIPTION

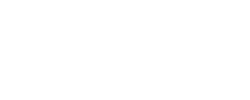

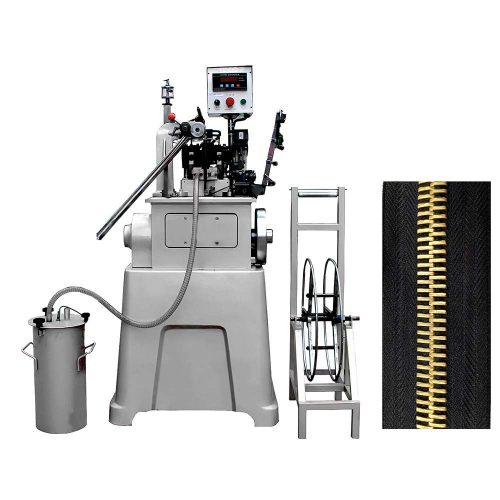

This machine is used to plate anti silver color on metal zipper, and it also can be used to plate anti brass and nickel color for metal zippers, having functions of automatic oil cleaning, color fixing, twice color plating, several washing and dewatering. The zipper after polished and plated by this machine can be ironed and applied lacquer directly. No tape collecting and releasing process is needed.

The tank body of this machine is made from imported anti-corrosive PP materials, and all steel parts are made from stainless steel 316# and 304#, and the electrical components are mainly from Schneider. Customer can choose steam or electrical heating system and ultrasonic oil cleaning system according to space situation. This machine has chemical collection system, tension control system and chemicals high pressure spraying coloring system.

| Machine Model | Average Output | Total Power | Voltage |

Machine Size(cm) L×W×H |

| QLQ-CCPMD-2 | 2000-2500M/H | Electrical Heating:16.8KW Steam Heating:6.8KW |

380V | 630*95*150 |

Advantages:

1- This machine adds color fixing process based on traditional anti silver plating process, making plated color more stable with better color fastness.

2- User can adjust tape running way to achieve one machine available for plating colors including anti silver, anti brass and nickel.

3- Flap wheels mixing system and air mixing system are added in the tank, making faster and more even plating and more clean after washing.

4- High pressure spraying system can wash the remained chemicals on tape more clean, preventing tape discoloring and saving 20%-30% water.

5- Scientific tension system can effectively control the industry difficulty of scratching plated coating by too tight tension and zipper winds around the main shaft by too loose tension.

6- Chemical collection system can be chosen. Collecting chemicals on the tape for recycling can stop wasting and decrease the cost for pollution process.

7-According to investigation data, using our automatic plating machine in pre-process (chain zipper process) can save laboring 30%-50%, and improve efficiency 20%-30% in after-process (finished zipper process).

8-To make sure machine body will not be deformed and better for transportation, the machine are divided into two parts.

9-All excellent materials from famous branded suppliers at home and abroad makes quality guarantee coefficient increased 5 times.

--500x500.jpg)