Description

Production Description

Take 200L for example:

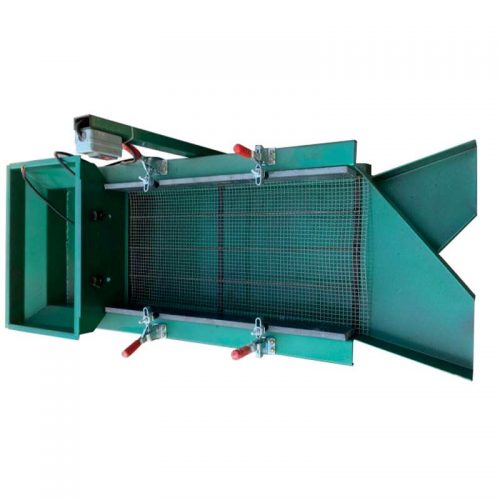

| Model No. | QLQ-200VTPM |

| Powe | 380V,3PH,3KW,50HZ |

| M/C size | 1.26*1.23*0.96M |

| N.W. | 420KG |

| G.W | 470KG |

Advantages:

1. Vibration and Rotation Mechanism: A vibrating type polishing machine operates by combining both vibration and rotation. It has a vibrating platform or bowl that contains the workpieces, and it oscillates and rotates simultaneously. These dual movements ensure an effective and even distribution of abrasives, polishing compounds, or media across the surface of the workpieces, resulting in a consistent and uniform finish.

2. Efficient Polishing Process: The vibrating motion of the machine enhances the polishing process by enabling the abrasives or media to reach all areas of the workpiece, including internal cavities, corners, and intricate contours. This allows for a thorough and efficient polishing action, saving time and ensuring a high-quality finish on complex parts or components.

3. Versatile Applications: Vibrating type polishing machines can be used on a wide range of materials, including metals (such as steel, aluminum, or brass), plastics, ceramics, glass, and even precious stones. This versatility makes them suitable for various industries, including jewelry making, metalworking, and even for polishing delicate electronic components.

4. Surface Restoration and Finishing: These machines are particularly effective in restoring worn-out or dull surfaces to their original shine. They can remove scratches, oxidation, burrs, or other surface imperfections, thereby improving the aesthetic appeal of the workpieces. Additionally, vibrating type polishing machines are capable of providing different levels of surface finishes, ranging from matte to high-gloss, based on the specific requirements of the application.