Description

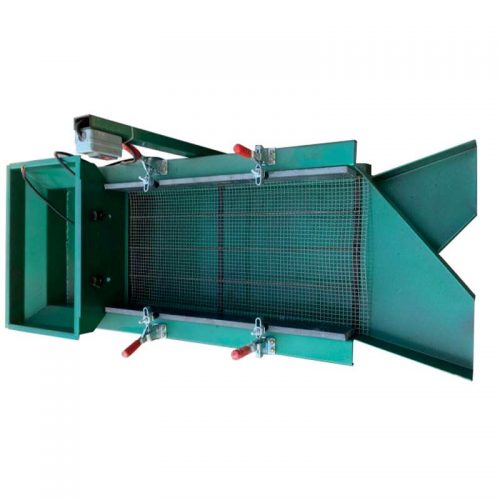

| Output |

For slider is about 30kg/time/40-60mintes For puller is about 50kg/time/40-60minutes |

| Power | 380V,1.1KW,3PH |

| N.W. | 800 KGS |

| G.W. | 850KGS |

| Size | 1.75*0.95*1.30M |

| Polishing time | about 40-60mins |

Advantages:

1. Whirlpool Motion: A whirlpool type polishing machine utilizes a swirling motion to polish the workpieces. It has a rotating bowl or container where the workpieces are placed. The rotation of the bowl creates a swirling whirlpool effect, allowing the polishing media or abrasives to flow and circulate around the workpieces evenly. This motion ensures efficient polishing action on all surfaces, including complex shapes and internal cavities.

2. Uniform Polishing: The whirlpool motion of the polishing machine ensures uniform polishing on the workpieces. As the polishing media or abrasives circulate in the container, they make contact with all areas of the workpiece surface, resulting in a consistent finish. This is particularly beneficial when polishing intricate or irregularly shaped parts, as it ensures that no area is left untreated.

3. Versatile Applications: Whirlpool type polishing machines can be used for a wide range of materials, including metals (such as steel, aluminum, or brass), plastics, ceramics, glass, and even precious stones. This versatility makes them suitable for various industries, including jewelry making, metalworking, and electronics manufacturing. They can effectively polish different types of workpieces, from small components to larger parts.

4. Surface Restoration and Finishing: These machines are highly effective in restoring worn-out or dull surfaces to their original shine. They can remove scratches, oxidation, burrs, or other surface imperfections, thereby improving the overall appearance and quality of the workpieces. Additionally, whirlpool type polishing machines can be used to achieve different levels of surface finishes, ranging from matte to high-gloss, based on the specific requirements of the application.

5. Adjustable Settings and Controls: Whirlpool type polishing machines often offer adjustable settings and controls to customize the polishing process according to specific materials and finishing requirements. Operators can adjust the rotational speed, direction, and even the type and size of polishing media or abrasives used. This flexibility allows for precise control over the polishing parameters, ensuring optimal results for different workpiece materials and surface finish preferences.